Managing Noise and Preventing Hearing Loss

Noise as a Hazard

Excessive noise exposure causes permanent, irreversible hearing loss. Construction work involves many noise-producing activities making hearing protection essential.

Common Construction Noise Sources:

- Power tools (grinders, saws, nail guns, jackhammers)

- Heavy plant and equipment (excavators, loaders, compactors)

- Concrete cutting and drilling

- Impact tools (jackhammers, post drivers)

- Generators and compressors

Noise-induced hearing loss is permanent and cannot be reversed. Prevention is the only solution.

Exposure Standards

WHS Regulation 56:

- LAeq,8h = 85 dB(A) (8-hour time-weighted average)

- LC,peak = 140 dB(C) (peak noise level)

What this means:

- Average noise over 8 hours must not exceed 85 dB(A)

- Instantaneous peak noise must not exceed 140 dB(C)

Indicative Noise Levels:

- Normal conversation: 60 dB(A)

- Busy traffic: 80 dB(A)

- Lawn mower: 90 dB(A)

- Chainsaw: 110 dB(A)

- Jackhammer: 120 dB(A)

If you need to raise your voice to talk to someone 1 meter away, noise levels are likely approaching or exceeding 85 dB(A).

Who Has Duties?

PCBUs

Must:

- Identify noise hazards

- Assess risks of hearing damage

- Eliminate or minimize noise exposure

- Ensure exposure below standards

- Provide hearing protectors if engineering controls insufficient

- Provide information and training

- Conduct audiometric testing where required

Designers, Manufacturers, Suppliers

Must:

- Design plant to minimize noise generation

- Provide noise emission data

- Include noise control features in equipment

Risk Management Process

1. Identify Hazards

Indicators of Noise Hazard:

- Need to shout to be heard 1 meter away

- Ringing ears or muffled hearing after work

- Complaints from workers about noise

- Noise complaints from neighbors/public

Review:

- Manufacturer specifications for equipment (noise ratings)

- Previous noise assessments

- Incident reports

2. Assess Risks

When Noise Assessment Required:

- Uncertain if exposure exceeds standards

- To verify control effectiveness

- After changes to work processes or equipment

Who Conducts Assessment:

- Competent person (occupational hygienist, acoustician)

- Uses calibrated sound level meters

- Personal noise dosimeters for individual exposure

3. Control Risks: Hierarchy of Control

Level 1: Elimination

- Modify process to not require noisy equipment

- Example: Use mechanical fixing instead of impact tools where possible

Level 2: Substitution

- Replace with quieter equipment or methods

- Example: Electric tools instead of pneumatic tools

- Example: Hydraulic splitters instead of jackhammers

Level 2: Isolation

- Separate workers from noise source

- Relocate noisy equipment away from workers

- Establish noise exclusion zones

- Remote operation of noisy plant

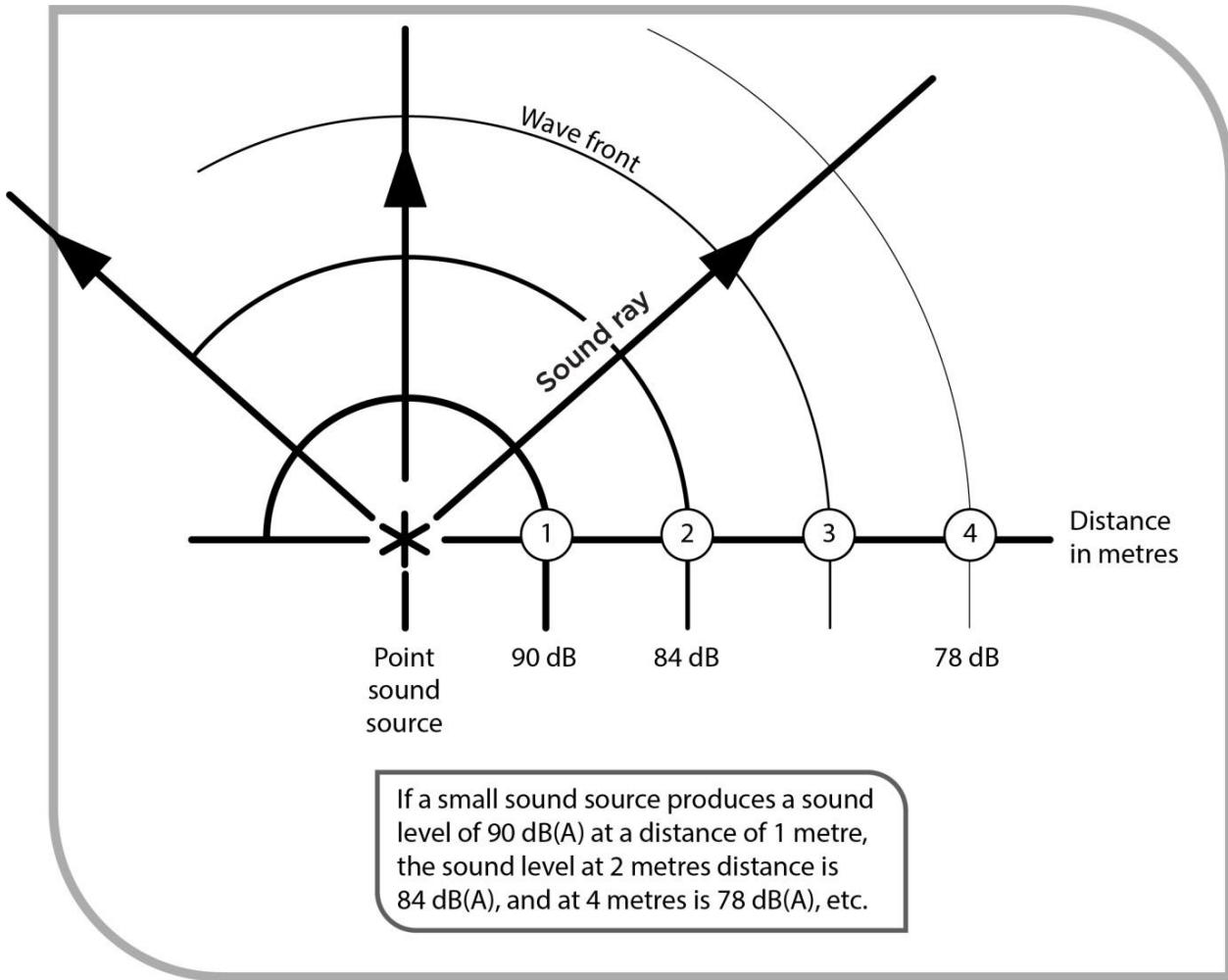

Figure: Sound is reduced by about 6 dB for each doubling of distance

Figure: Sound is reduced by about 6 dB for each doubling of distance

Level 2: Engineering Controls

Noise Reduction at Source:

- Install mufflers on exhaust systems

- Use damping materials on vibrating surfaces

- Maintain equipment (worn parts increase noise)

- Enclose noisy equipment in acoustic barriers

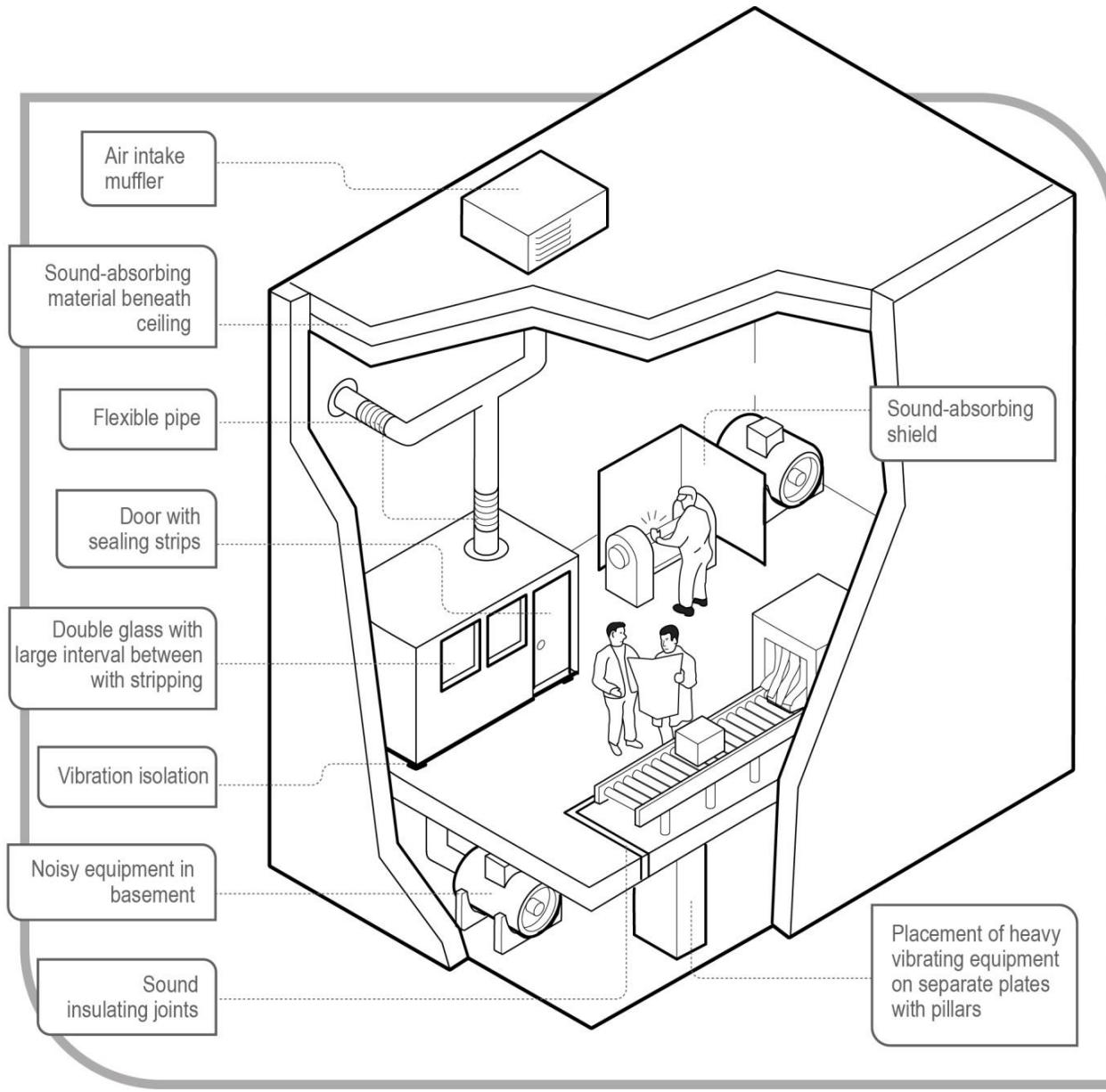

Figure: Examples of noise control measures (enclosures, isolation)

Figure: Examples of noise control measures (enclosures, isolation)

Example: Fit compressor with acoustic enclosure and muffled exhaust.

Barriers and Screens:

- Acoustic barriers between noise source and workers

- Sound-absorbing materials in enclosed spaces

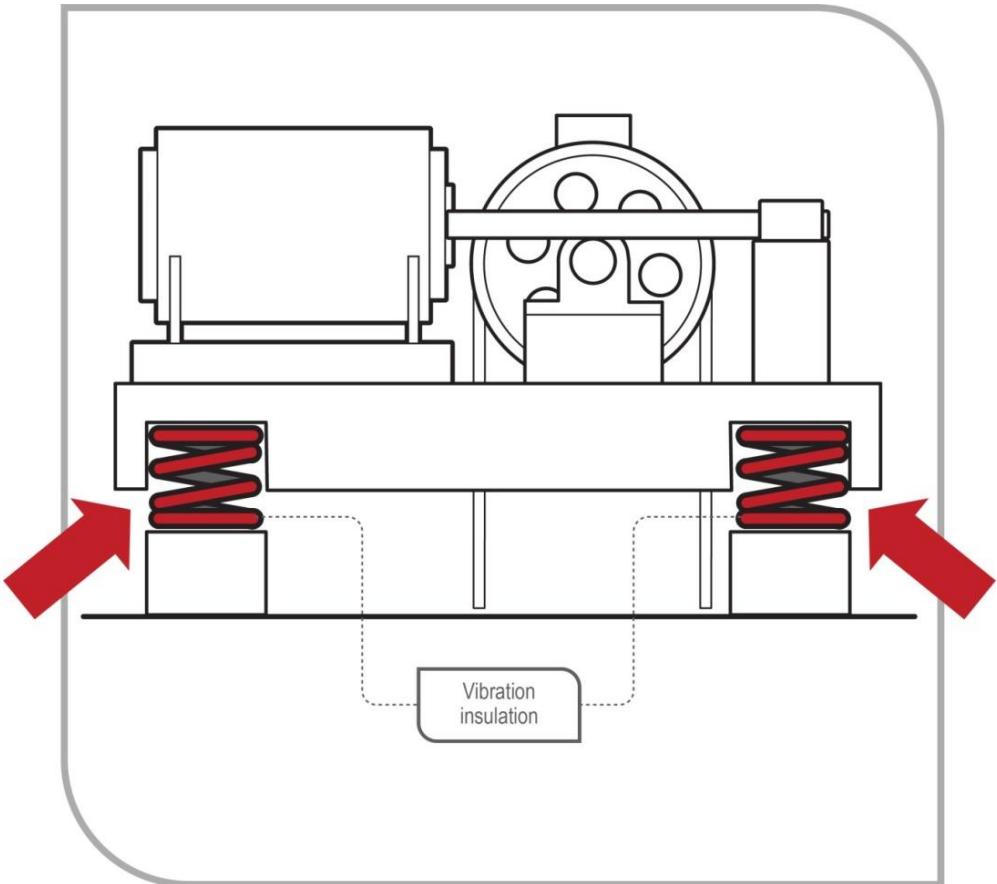

Figure: Isolating machine vibration from structure

Figure: Isolating machine vibration from structure

Maintenance:

- Regular maintenance reduces noise (worn bearings, loose parts)

- Replace damaged mufflers and acoustic seals

Level 3: Administrative Controls

- Limit time workers exposed to high noise

- Job rotation to reduce individual exposure

- Restrict access to high-noise areas

- Schedule noisy work when fewer workers present

Level 3: Personal Protective Equipment

Hearing protection is least effective control. Use only after higher controls implemented.

Types of Hearing Protection:

Earplugs:

- Foam, pre-molded, or custom-fitted

- Inserted into ear canal

- Typical reduction: 20-30 dB

Earmuffs:

- Cushioned cups over ears

- Typical reduction: 20-35 dB

- More visible (easier to check compliance)

Selection:

- Must provide sufficient attenuation to reduce noise below 85 dB(A)

- Consider comfort (workers more likely to wear)

- Hygiene (clean, replace when worn)

Limitations:

- Only effective when worn correctly and consistently

- Gaps or poor fit reduce effectiveness dramatically

- Workers may remove during breaks but still in noisy area

4. Maintain and Review

- Inspect and maintain noise control equipment

- Monitor noise levels after changes

- Check hearing protector condition

- Review after workers report hearing issues

- Conduct audiometric testing

Audiometric Testing

When Required (WHS Reg 58): If worker exposed to noise exceeding standards and at risk of hearing loss.

What it Involves:

- Baseline hearing test (before exposure)

- Periodic re-testing (annually for high-risk, every 2 years otherwise)

- Conducted by qualified person (audiologist, audiometrist)

- Identifies early signs of hearing loss

Benefits:

- Detects hearing loss early

- Allows intervention before significant damage

- Confirms control measures working

Worker Rights:

- Access to test results

- Confidential health information

- No cost to worker

Practical Construction Example

Scenario: Concrete cutting for service trenches

Hazard Identification

- Petrol-powered concrete saw generates 110 dB(A)

- Workers cutting for several hours per day

- Other workers in vicinity

Risk Assessment

- High risk: Exposure well above 85 dB(A)

- Operator and nearby workers affected

Controls Implemented

Engineering:

- Selected electric saw (quieter than petrol, 95 dB(A))

- Acoustic barrier erected around cutting area

- Work during day (fewer workers on site)

Isolation:

- Exclusion zone 5 meters from saw

- Only operator and one offsider in zone

- Signage indicating high-noise area

Administrative:

- Limit continuous cutting to 1-hour blocks

- Job rotation among qualified operators

- Advance notice to other trades (relocate if possible)

PPE:

- Class 5 earmuffs for operator (30 dB reduction)

- Earplugs for offsider (25 dB reduction)

- Hearing protection mandatory in exclusion zone

Monitoring

- Noise assessment confirmed exposure <85 dB(A) with controls

- Audiometric testing arranged for regular operators

Other Noise Effects

Ototoxic Substances

Exposure to certain chemicals (ototoxic substances) can result in hearing loss or exacerbate the effects of noise.

- Solvents: Toluene, xylene, styrene

- Heavy Metals: Lead, mercury

- Asphyxiants: Carbon monoxide

Control measures must consider both noise and chemical exposure.

Tinnitus

Ringing, buzzing, or whistling in ears. May be temporary or permanent.

Communication and Safety

High noise:

- Impairs communication

- Prevents hearing warning signals

- Masks approaching vehicles/equipment

- Increases accident risk

Controls:

- Visual warning signals in high-noise areas

- Hand signals for communication

- Flashing lights on mobile plant

Stress and Fatigue

Prolonged noise exposure causes:

- Increased stress levels

- Mental fatigue

- Reduced concentration

- Lower productivity

Information and Training

Workers must be informed about:

- Risks of noise exposure and hearing loss

- Noise levels in their work areas

- How to use and maintain hearing protection

- How to identify when noise controls not working

- Audiometric testing requirements

- Reporting hearing changes