Managing Electrical Risks

Electrical Hazards

Electricity is essential on construction sites but presents serious hazards:

Electric Shock:

- Current passes through body

- Can cause death, severe burns, falls from height

- Low voltages (< 50V AC/120V DC) generally safe, but not always

- 230V AC (standard power) can kill

Arc Flash and Burns:

- Electrical faults create intense heat and light

- Severe burns, eye damage, ignition of materials

Fire and Explosion:

- Faulty wiring, overloaded circuits

- Ignition of flammable materials/atmospheres

Secondary Injuries:

- Falls from height after shock

- Injuries from muscle contractions

Electricity kills quickly. Even brief contact with live parts can cause cardiac arrest.

Who Has Duties?

PCBUs

Must:

- Ensure electrical equipment safe

- Maintain electrical installations

- Use licensed electrical workers for electrical work

- Provide RCDs (residual current devices)

- Test and tag equipment

- Manage risks from overhead/underground electrical services

Licensed Electrical Workers

Only licensed electricians may perform electrical work (installation, alteration, maintenance, repair of electrical equipment).

Exceptions (general workers may perform):

- Replacing lamps, fuses

- Plugging/unplugging equipment

- Resetting RCDs or circuit breakers

Risk Management Process

1. Identify Hazards

Construction Site Electrical Hazards:

- Overhead powerlines

- Underground cables

- Temporary site wiring

- Damaged cables and equipment

- Wet conditions

- Metal scaffolding near electrical sources

- Inadequate RCD protection

2. Assess Risks

Higher Risk Situations:

- Contact with overhead powerlines (cranes, EWPs, scaffolding, long materials)

- Excavation near underground cables

- Wet/damp environments

- Use of metal ladders or scaffolding

- Damaged or poorly maintained equipment

3. Control Risks: Hierarchy of Control

Level 1: Elimination

- Eliminate need for electrical equipment (use battery/pneumatic tools)

- De-energize powerlines before work near them

Example: Request electrical utility to isolate and earth overhead lines before crane operation.

Level 2: Substitution/Engineering

Isolation and Earthing:

- De-energize electrical equipment before work

- Lockout/tagout procedures

- Earthing of de-energized systems

Insulation:

- Insulated cables and equipment

- Insulation barriers around live parts

- Insulated tools for electrical work

Residual Current Devices (RCDs):

- Detects leakage current, disconnects power instantly

- Mandatory for construction sites (WHS Reg 164)

- 30 mA maximum for socket outlets supplying equipment

Double Insulation:

- Equipment with extra layer of insulation

- Marked with double square symbol

- Reduces shock risk

Extra-Low Voltage (ELV):

- Systems ≤50V AC or ≤120V DC

- Reduced risk of electric shock

- Example: 12V or 24V power tools

Physical Barriers:

- Guards around switchboards, junction boxes

- Fencing/barricades around substations

- Covers over floor boxes

Level 3: Administrative/PPE

- Safe work procedures

- Electrical safety training

- Permit systems for work near live parts

- Exclusion zones around overhead powerlines

- PPE (insulated gloves, dielectric footwear) - for electrical workers only

- Safety Observers: Must be competent to rescue and resuscitate (assessed in previous 12 months) for energized work.

4. Maintain and Review

- Regular testing and inspection

- Test and tag portable equipment

- RCD testing (push test button monthly, full test every 6 months)

- Replace damaged cables immediately

RCDs (Safety Switches)

How RCDs Work: Monitors current flow. If imbalance detected (leakage to ground through person), disconnects power within 30 milliseconds.

Types of RCDs

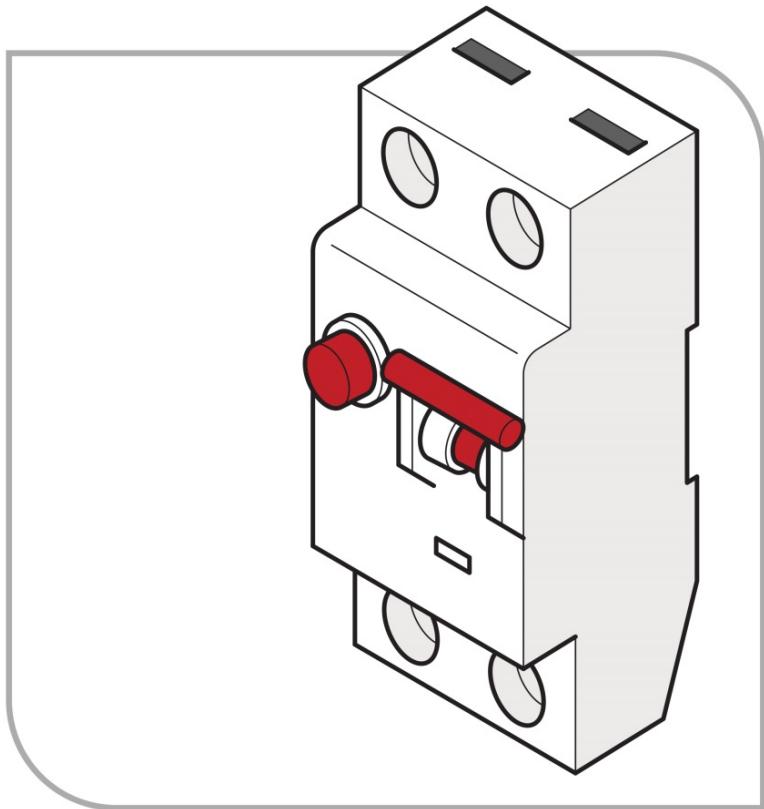

Figure: Switchboard RCD unit

Figure: Switchboard RCD unit

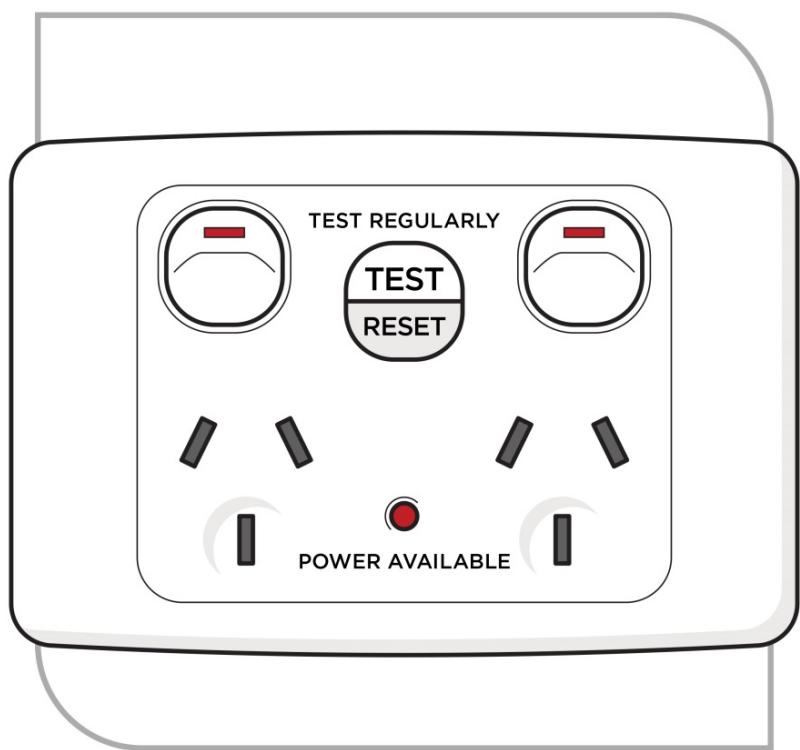

Figure: Fixed socket outlet RCD unit

Figure: Fixed socket outlet RCD unit

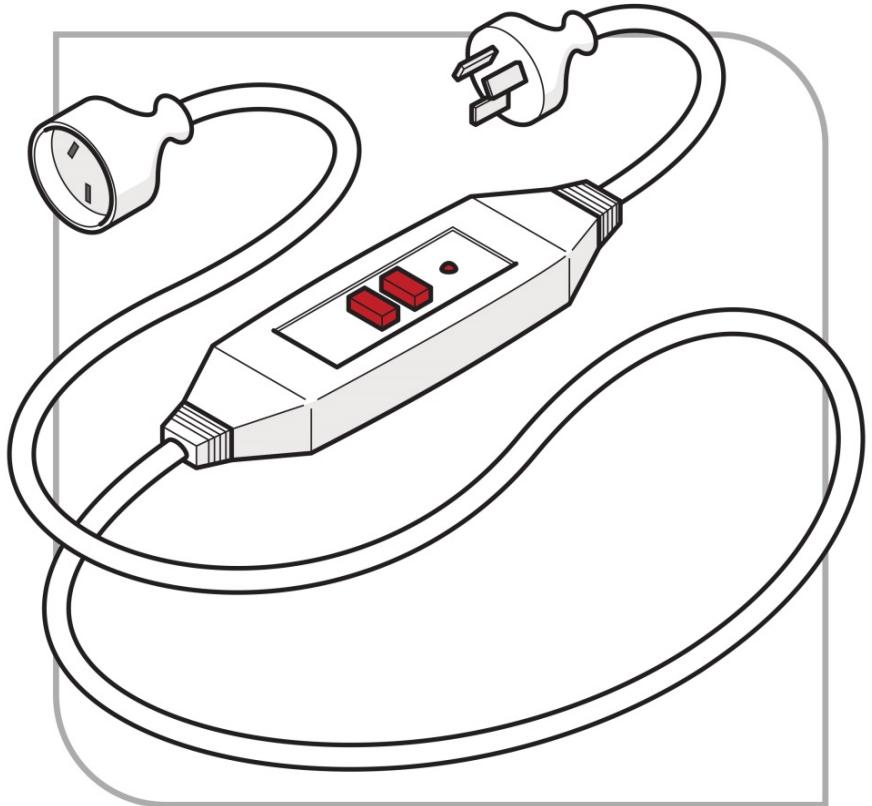

Figure: Portable RCD fitted directly to power cable

Figure: Portable RCD fitted directly to power cable

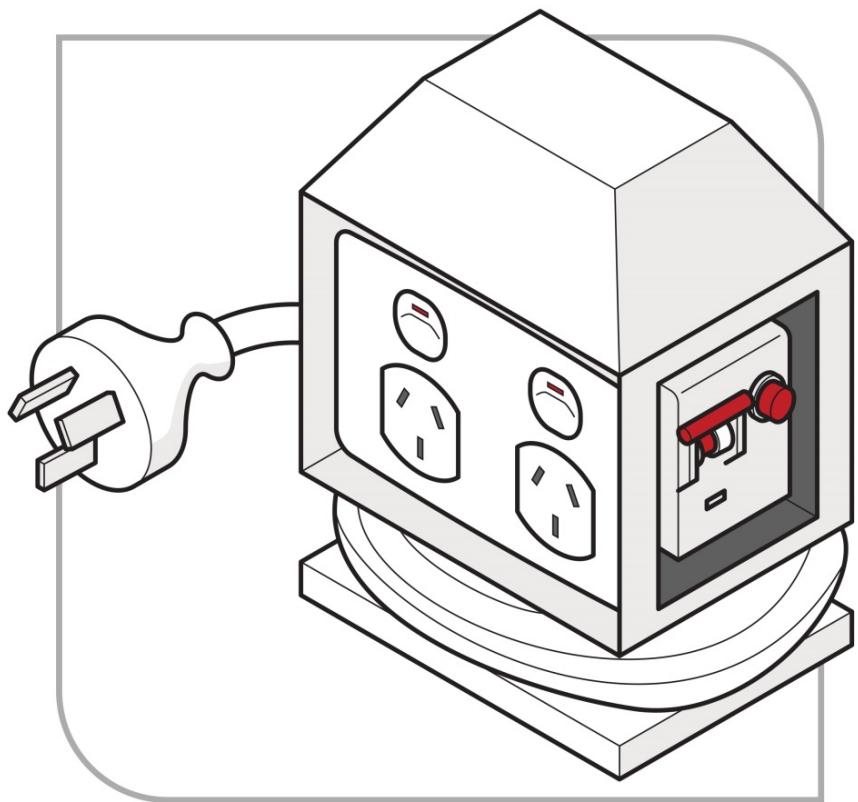

Figure: Portable RCD protected power board

Figure: Portable RCD protected power board

Requirements for Construction:

- RCD protection for all socket outlets supplying portable equipment

- Portable RCDs if fixed RCDs not available

- Test before each day's use (push test button)

RCDs are the primary protection against electric shock on construction sites. Never bypass or disable.

Overhead Powerlines

Extreme Risk: Contact with overhead powerlines causes many construction fatalities.

Affected Activities:

- Crane operations

- Elevated work platforms

- Scaffolding erection

- Carrying long materials (pipes, ladders, formwork)

- Tipping trucks (raised bodies)

- Tree work

Safe Approach Distances

For voltages ≤132,000V:

- Non-electrical workers: Maintain safe approach distances as determined by the electricity supply authority (typically 3 meters, check local regulations)

- Licensed electrical workers: Refer to AS/NZS 4836

For voltages >132,000V:

- Greater distances apply - check with electrical authority

When operating plant, increase distance to 6 meters or more. Account for boom swing, load sway, vehicle movement.

Control Measures

Preferred (Level 1):

- De-energize and earth powerlines for duration of work

If De-Energization Not Practicable:

- Install physical barriers (goal posts, height markers)

- Appoint spotter to watch clearances

- Use insulated/non-conductive equipment

- Establish exclusion zones

- Continuous communication between spotter and operator

Example: Crane work near powerlines - Request utility to de-energize lines, or install goal post barriers and appoint dedicated spotter.

Underground Cables

Risk: Striking underground cables during excavation causes electrocution, burns, explosions.

Before Excavating:

- Dial Before You Dig (1100) - Obtain service location plans

- Locate services on ground (use plans, cable locators)

- Mark services clearly (paint, pegs)

- Expose services carefully (hand dig within 500mm)

- Inspect services (confirm type, depth, condition)

- Support and protect services during work

Free service provides plans showing underground services. Call 1100 at least 2 business days before excavating.

Safe Excavation Procedure

- No mechanical excavation within 500mm of marked services

- Hand tools only (spades, shovels - not picks or mattocks)

- Assume unidentified cables are live

- Locate all services even if only one type expected

- Support services crossing trenches

- Restore covers before backfilling

Temporary Site Wiring

Installation:

- Licensed electrician only

- Adequate capacity for loads

- Protected from damage (elevated or buried)

- RCD protection on all socket outlets

Cables:

- Heavy-duty flexible cables (not domestic cable)

- Supported off ground where practical

- Protected from traffic, plant, sharp edges

- No joins in cables (use correct length)

Switchboards:

- Weather-protected enclosures

- Secured to prevent movement

- RCDs installed and labeled

- Accessible for testing/maintenance

Test and Tag

Portable electrical equipment must be regularly tested and tagged:

Visual Inspection:

- Damage to cables, plugs, casing

- Strain relief intact

- Correct rating for use

Electrical Testing:

- Earth continuity

- Insulation resistance

- RCD function (if built-in)

- Conducted by competent person

Testing Frequency:

- Construction sites: Every 3 months (high-risk environment)

- Other workplaces: 6-12 months depending on environment

Tagging:

- Tag shows test date, next test due, tester details

- Do not use untagged equipment

Wet Conditions

Increased Risk: Water conducts electricity - wet conditions greatly increase shock risk.

Controls:

- Keep equipment dry (covers, shelters)

- Use waterproof equipment rated for wet use (IP rating)

- Use 10mA portable RCDs

- Extra-low voltage tools (12V/24V)

- Delay work until conditions dry where possible

Damaged Equipment

Never use damaged electrical equipment:

- Frayed or cut cables

- Broken plugs or sockets

- Cracked casings

- Damaged switches

Action:

- Tag as defective ("DO NOT USE")

- Remove from service

- Arrange repair by electrician or disposal

Practical Construction Example

Scenario: Installing steel formwork near 11kV overhead powerlines

Hazards Identified

- Formwork panels 3.6m long (unwieldy)

- Overhead powerlines 5m above ground

- Risk of contact during lifting/placing

- Metal formwork conducts electricity

Risk Assessment

- Extreme risk: Powerline contact = electrocution, arc flash

Controls Implemented

Engineering (Level 1):

- Powerlines de-energized by electrical utility for 4-hour work period

- Isolation confirmed and earthed

Administrative:

- Permit to work issued by utility

- Work scheduled within de-energized period

- All workers briefed on powerline location

- Spotter assigned to monitor work area

If De-energization Not Available: Would implement:

- Goal post barriers at 6m from powerlines

- Spotter with authority to stop work

- Pre-assembled formwork on ground to minimize lifting near lines

- Exclusion zone barricaded

Result

Work completed safely with powerlines de-energized. Zero risk of electrical contact.

Information and Training

Workers must know:

- Risks of electricity

- How to identify electrical hazards

- Importance of RCDs and how to test

- Not to use damaged equipment

- Overhead and underground powerline risks

- Who to contact if electrical issues arise

- Emergency response to electric shock

Emergency Response - Electric Shock

If someone receives electric shock:

- Do not touch the person if still in contact with electricity

- Turn off power at switchboard if safe to do so

- Call 000 immediately

- If power cannot be turned off, use non-conductive material (dry wood) to separate person from source

- Begin CPR if trained and person not breathing

- Continue until ambulance arrives

Do not become a second victim. Never touch someone in contact with electricity until power disconnected.